Here we go…

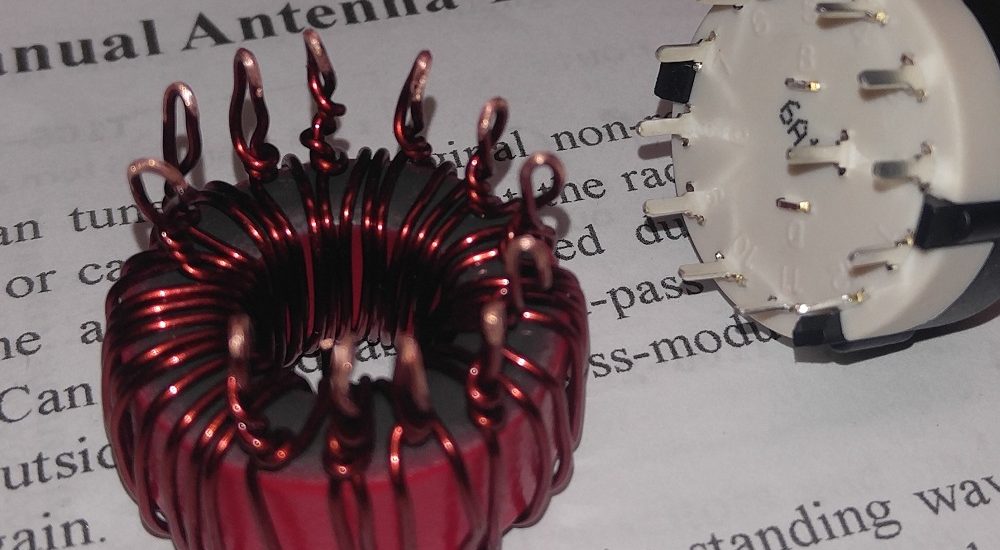

I’m new to kit building, and pretty open to expanding and testing my skills. In looking through stories of others building kits, I became extremely intimidated by the horrible stories of seasoned builders would absolutely never tackle kits including toroids that must be wound by hand. Seemed that kit designers were somehow asking too much of builders if they required these small donuts to be wrapped a few times with wire. Certainly this was something I should avoid being such a novice.

Being hard headed, I tried it myself on a few small projects, and all I have to say is…

Mule fritters!

These people had me all scared for nothing! All you have to do is keep your head about you, count the windings, and try to keep the turns even. If you can shuffle a deck of cards without playing 52 card pickup, you can wind a toroid.

Here’s Cam’s tips for winding these intimidating little things:

- If the wire goes through the hole, it counts. Yes, any pass through the center of the toroid counts as a winding.

- Left hand rule. Most toroids assume you are wrapping over the close side, into the middle, and towards the right (left hand fingers grab through the donut, and wrap in direction of thumb)

- Go get the magnifying glass. Don’t want to hear it, go get it now, because you won’t read the next point.

- Take your time. Don’t rush it. Have a frosty beverage if so inclined… but don’t rush or your hands will sweat, your eyes will squint, your tongue will get bit, you’ll have to get some ice, and forget how many turns you’ve completed.

- Taps are no excuse to say you can’t do it. Just loop the wire an inch wide towards the bottom, loop the rest through the toroid again, and twist the loose loop a couple times. This will be sanded/soldered, later, so don’t worry about it, just get through it (Stop worrying! Nobody will see it in the box anyways!).

- If it’s small, borrow a tapered dowel, or knitting needle that you can slide it down on to hold things. Don’t push down too tight, or you could damage the toroid.

- When complete, leave some wire hanging until you’re ready to mount. Yup, I’ve done it. Overdid it on the frosty beverage.

- When ready to mount, sand the varnish off the end, then remove the rest by getting a big blob of solder on your soldering iron, and run the wire through there watching all the non-wire stuff come off in the solder. Go ahead and clean the tip of the soldering iron afterwards, I don’t care if you DO think you can reuse that solder.

Don’t just take it from me. Here are some videos of others showing you the right way to do it. If you go through all this, and still think you can’t do it, … well, … I can only do so much. Happy winding!